The production process of flat glass typically involves the following steps:

- Raw Materials: The main ingredients for making flat glass are silica sand, soda ash, and limestone. Other additives such as dolomite, feldspar, and recycled glass cullet may also be used. These materials are carefully selected and mixed to achieve the desired composition.

- Batch Preparation: The raw materials are mixed together in the correct proportions according to the desired glass composition. This mixture is called the batch. It is then heated in a furnace to form a molten glass.

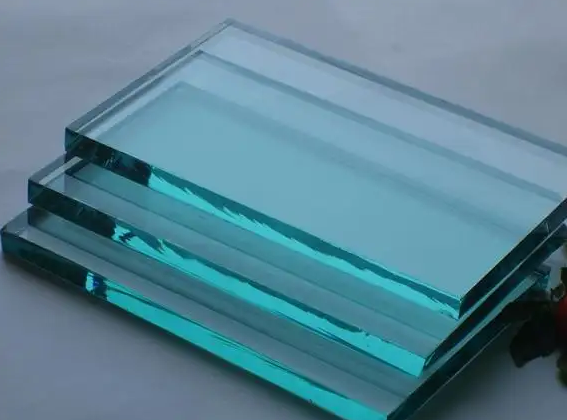

- Float Glass Method: The most common method for producing flat glass is the float glass process. In this method, the molten glass is poured onto a bath of molten tin. As the glass floats on the tin, it spreads out and forms a continuous ribbon of uniform thickness.

- Annealing: The glass ribbon is gradually cooled in a controlled manner to relieve internal stresses and increase its strength. This process is known as annealing and is essential to ensure the glass’s stability and durability.

- Cutting and Shaping: Once the glass ribbon is fully cooled and solidified, it is cut into large sheets of desired dimensions. Various cutting and shaping techniques, such as scoring and breaking or using automated cutting machines, are employed to create individual glass panels.

- Cleaning and Inspection: The cut glass panels undergo a thorough cleaning process to remove any impurities or residues. They are then inspected for any defects, such as bubbles, scratches, or unevenness. Defective panels are discarded or recycled.

- Further Processing: Depending on the intended application, the flat glass may undergo additional processing steps. This can include tempering (heating and rapid cooling to increase strength), laminating (bonding multiple layers with an interlayer for safety or sound insulation), coating (applying special films or coatings for optical or thermal properties), or other treatments as required.

- Packaging and Distribution: The final step involves packaging the flat glass panels to protect them during transportation and storage. The glass is usually packed in crates or racks, and proper labeling and handling instructions are provided. The packaged glass is then distributed to customers, such as construction companies, automotive manufacturers, or other industries that utilize flat glass in their products or projects.

It’s worth noting that the specific details of the production process can vary depending on the manufacturer, the type of glass being produced, and the desired quality standards.